Back to PP Drainage & Sewer Systems

BlackMax® Drainage Pipes and Fittings

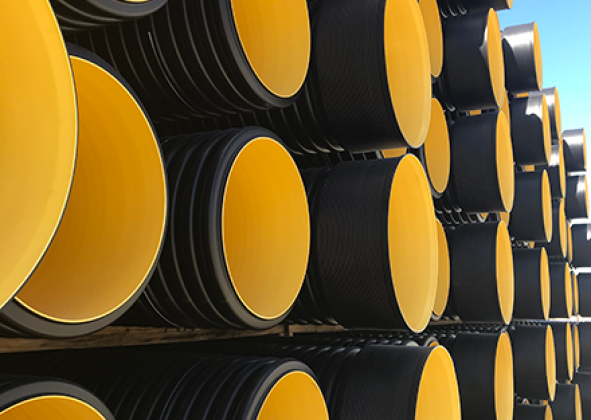

BlackMax® offers exceptional hydraulic and structural performance and is recognised for its durability and low cost benefits compared with other conventional drainage pipes or culverts. Manufactured from polypropylene, BlackMax® drainage pipes are resistant to corrosive and aggressive ground conditions, resulting in years of corrosion free service. Contact us for a quick & easy quote on any item within the BlackMax® range.

Filters CLOSE

Our BlackMax® Drainage Pipes and Fittings range

Use the filters below to refine your search criteria

Applications

Material Options

Product Details

Handling & Storage

Installation & Testing

FAQ

Case Studies

Applications

Applications

BlackMax® is an Iplex structured wall polypropylene pipe system designed for non-pressurised gravity drainage systems. The BlackMax® storm water drainage range includes high-quality fittings to enable full installation versatility during installation.

Iplex BlackMax® pipes and fittings offer effective drainage solutions and are suitable for installation in the following applications:

- Stormwater drainage pipelines

- Road culverts

- Gravity Sewer mains

- Low head Irrigation

- Rehabilitation (as liner pipe)

- Ventilation ducts

- Leachate collection

- Stormwater retention systems

- Estuarine and Ocean outfalls

BlackMax® Technical Guide

Advantages

Throughout Australia, BlackMax® drainage pipes and fittings have been chosen as the stormwater drainage product of choice because of its unique characteristics and cost effective benefits during installation.

| Features | Benefits |

| Durability | The tough, ductile nature of polypropylene enable BlackMax® drainage pipes to resist impact sustained in course of transportation and site handling, without damage. |

| Abrasion and corrosion resistant | Polypropylene tubes and fittings are notably resistant to abrasion and have excellent resistance to corrosive drainage. The material is resistant to aggressive ground conditions, such as acid sulphate soils or saline ground waters. |

| Effective rubber ring joint | Designed for ease of assembly and jointing. Pipes can be cut to length on site and rejoined. |

| Low embodied energy | Environmental benefits. |

| Inground performance | High tolerance to deformation and can accommodate soil movement without structural damage. |

| Smooth bore for hydraulic performance | Combined with their high resistance to scale and sediment build up provides excellent hydraulic performance. This can result in reduced grades to accomplish a given flow. |

| Lightweight for ease of installation | Can be easily manoeuvred in confined areas by hand or with light lifting equipment. Site handling and efficiency is therefore improved, which can result in significant savings on installation. |

| Choose From An Extensive Range of Fittings | A range of standard fittings in all sizes is available for use with BlackMax® pipes providing a complete pipeline system.BlackMax® stormwater drainage fittings in sizes DN225, DN300 and DN375 are fabricated from PVC pipe sections with molded socketed ends. DN450, DN525 and DN600 fittings are fabricated from BlackMAX® (PP) pipe sections and are generally supplied with socketed ends for rubber ring jointing.Other configurations, such as spigot ends are also available upon request with separate pipe couplings for jointing.Repair clamps and jointing clamps are available from Iplex providing a quick and permanent solution for repairing damaged BlackMax® pipes or pipe jointing. |

Material Options

Material Options

Mechanical Properties

| Property | Value & Unit |

| Density | 900 kg/m³ |

| Design Stress | 17.5 MPa |

| Ultimate Tensile Strength | 31.0 MPa |

| Ring Bending Modulus | 1300 MPa |

| Tensile Modulus | 3000 MPa |

| Poisson’s Ratio | 0.45 |

Thermal Properties

| Property | Value & Unit |

| Max Continuous Service Temperature | 50°C |

| Specific Heat | 1045 J/kg.K |

| Thermal Conductivity | 0.138 – 0.150 W/m.K |

| Coefficient of Thermal Expansion | 7 x 10-5 / °C |

| Vicat Softening Temperature | >79°C |

Chemical Resistance

Polypropylene drainage pipes are inherently resistant to a wide range of chemicals such as acids, alkalis, salts, wetting agents and alcohols. It is however attacked by oxidising acids such as fuming nitric acid or hot concentrated sulphuric acid, neither of which should be encountered in a drain. Polypropylene is swollen and softened by halogenated solvents (for example, trichlorethylene) and hydro-carbon solvents such as xylene and benzene. However, the effect is not immediate and the occasional contact with solvents such as petrol or diesel is acceptable for PP pipes used for drainage and sewerage applications.

SBR seals are also resistant to a wide range of chemicals such as salt solutions, alkalis, glycols and some alcohols. SBR is swollen by a number of organic solvents, however, the seals are encapsulated in the pipe profile and to a large extent, isolated from the contents of the pipe. As only a small part of the seal surface is in contact with liquid in the pipeline, any occasional spillages or illegal dumping of chemicals should have a minimal effect.

Product Details

Product Details

Standards and Approvals

Iplex BlackMax® pipes and fittings are manufactured to the Australian Product Standard under third-party accredited quality assurance system conforming to ISO 9001.

BlackMax® pipes have ISO Type 5 third-party StandardsMark™ Certification, License number SMKP20603; in accordance with AS/NZS 5065 “Polyethylene (PE) and polypropylene (PP) pipes and fittings for drainage and sewerage applications”.

BlackMax® pipes and fittings have been appraised by Water Services Association of Australia (WSAA) for performance compliance with AS/NZS 5065 (WSAA Appraisal 03/05).

Environmental Credentials

Iplex have published verified Environmental Product Declarations (EPD) on our range of Polypropylene pipes. EPDs are third-party certified documents based on ISO 14025 and EN 15804 Standards that communicate transparent and comparable information about the life-cycle environmental impact of a product or service. Specifically, product declarations include information on the environmental impact of raw material acquisition, energy use and efficiency, the composition of materials and chemical substances, emissions to air, soil and water and waste generation.

View Iplex’s BackMax® and SewerMax® polypropylene drainage pipes EPD

BlackMax® Pipe Dimensions

BlackMax® pipes are available in diameters ranging from DN225 through to DN1200 in SN8*.

*DN1000 to DN1200 coming soon.

BlackMax® Stormwater Drainage Fittings Range

We have a wide range of standard fittings for BlackMax® drainage and culvert pipes, including bends, tees, junctions, closed ends, couplings, plugs, reducers, saddles and adaptors. These drainage pipe fittings are manufactured for use with BlackMax® and SewerMax® pipes. Fittings can be fabricated from BlackMax® or SewerMax® pipe sections, PVC pipe sections, GRP / PVC and GRP / VC composite materials.

BlackMax® drainage pipe fittings in sizes DN225, DN300 and DN375 are generally fabricated from PVC pipe sections with moulded socketed ends for connection to BlackMax® pipe spigots. The use of PVC in these sizes provides improved manufacturing efficiencies and reduced costs compared with the PP fabrication process. The PVC BlackMax® range of fittings complies with Australian Standard AS/NZS 1260: “PVC-U pipes and fittings for drain waste and vent applications”.

BlackMax® stormwater drainage fittings in sizes DN450, DN525 and DN600 are fabricated from BlackMax® (PP) pipe sections and are generally supplied with socketed ends suitable for rubber ring jointing. Other configurations, such as all spigot ends, are also available on request with separate pipe couplings for jointing. DN100 and DN150 components are supplied with either PVC (RRJ or SWJ sockets) or standard solid wall polypropylene plain-ended spigots (110mm OD) and (160mm OD), allowing lateral side connections such as property branch connections. BlackMax® (PP) fittings comply with Australian Standard AS/NZS5065 “Polyethylene and polypropylene pipes & fittings for drainage and sewerage applications”.

GRP, GRP/PVC and GRP/VC composite fittings are manufactured specifically for use with SewerMax® pipes with socketed ends for connection to SewerMax® pipe spigots. GRP fittings are also available with PVC or VC socket or spigot ends for lateral connections to incoming PVC or VC sewer pipes. GRP SewerMax® fittings comply with Australian Standard Revision AS3571 “Glass reinforced thermosetting plastics (GRP) pipes – Polyester based – Water supply, sewerage and drainage applications”.

To view the full range of fittings and dimensions please view the BlackMax® and SewerMax® product range.

Design

BlackMax® Pipeline Design Hydraulic

BlackMax® pipelines fall into the smooth polymer pipe category of AS2200 “Design charts for water supply and sewerage’’ and provide exceptionally good hydraulic performance. However, these may in some instances be affected by various adverse service factors including:

- Growth of slime (varies with the age of the pipeline and available nutrient in the water)

- Siltation or settlement of suspended particulate matter

- Fitting types and configurations

For comprehensive details on hydraulic design, please refer to the BlackMax Technical Guide.

BlackMax® Pipeline Design Structural

In engineering terminology, BlackMax pipes are flexible pipes. They are designed to deform or deflect diametrically within

specified limits without structural damage after installation.

External soil and live loads on buried flexible pipes will cause a small decrease in vertical diameter and simultaneously an

increase in the horizontal diameter. The horizontal movement of the pipe walls into the soil material at the sides develops a

passive resistance within the soil to support the external load. The soil type and density and height of water table (if present),

all influence structural performance. The greater the effective soil modulus, the less the pipe will deflect and structural stability

against buckling is also enhanced.

Refer to the BlackMax Technical Guide for detailed information on appropriate structural design methods.

Handling & Storage

Handling & Storage

Although BlackMax® pipes are notably resistant to impact, they should not be rolled, dropped, thrown, or allowed to come into contact with sharp objects likely to cause damage.

When pipes are unloaded for storage they should be kept in their packs until required. The storage site should be level and free of obstructions

If pipes are not crated they should be placed on horizontal supporting timbers at approximately 2 metre centres

These timbers can also be used to separate layers when pipes are stacked individually.

Stack heights should be limited to prevent excessive ovalisation.

Sockets should be protected from distortion during storage by ensuring all of the sockets are placed at alternate ends and protruding from the stack.

For complete guidelines on handling and storing BlackMax pipes and fittings, refer to the BlackMax Technical Guide.

Installation & Testing

Installation & Testing

BlackMax® are flexible pipes designed for controlled deflection under vertical soil loads. These loads are then transferred to the soil in the side support zone. The Australian Standard AS/NZS 2566.2 “Buried flexible pipelines -Part 2 Installation” provides detailed information on appropriate methods for ensuring the side support zone in particular is correctly constructed.

The most critical aspect for the successful installation of these pipes is the selection and compaction of the embedment, i.e. the material in contact with the pipe. Embedment material should be of a granular nature, which is readily compactable. Crushed rock, aggregate and graded sand are commonly used but occasionally native soils, (eg. beach and mallee sand) may also be suitable provided they are free flowing and readily compacted.

Appendices G and H of AS/NZS 2566.2 provide extensive guidance on the selection and use of a wide range of embedment materials.

See the BlackMax Technical Guide for full installation instructions.

FAQ

Case Studies

Other PP Drainage & Sewer Systems products you may like…

Need help?

To speak with an Iplex sales & service team member