PVC-O

Iplex Apollo® is a bi-axially oriented PVC pressure pipe for use in water supply infrastructure. Iplex uses two patented processes resulting in an exceptionally tough, high-performance thermoplastic pipe with greatly enhanced physical characteristics, including greater impact resistance and reduced weight when compared with other PVC pipes. Apollo® PVC-O pipe also provides increased hydraulic capacity due to its exceptionally smooth and enlarged bore.

Applications

Applications

Due to its enhanced physical characteristics, Iplex Apollo PVC-O pipes are ideal for a wide variety high water pressure applications. The stronger material properties and exceptional hydraulic performance make this OPVC system optimal for:

- Major potable water supply trunk and reticulation mains

- Industrial process pipelines

- Recycled water pipelines

- Effluent pipelines for pumped sewage, industrial and rural wastes

- Slurry pipelines carrying corrosive mine waste water

- Irrigation and turf watering systems

Apollo® PVC-O Pressure Pipes - Product Catalogue and Technical Guide

Advantages

The increase in strength. toughness and ductility of biaxially oriented PVC permits the use of higher design stresses with improved overall performance.

The resulting larger internal bore reduces pumping costs and whole life costs. For the same head there is a greater flow capacity than the equivalent PVC-U or PVC-M pipe. This makes PVC-O pipes ideal for high pressure and high water flow rates.

| Features | Benefits |

| Excellent internal/external corrosion resistance | Long service life |

| Electrically non conductive | Do not suffer from electrolytic corrosion |

| Rieber rubber ring | Reduced jointing effort and improved reliability |

| Light weight | Ease of handling and reduced laying costs |

Material Options

Material Options

Mechanical Properties

| Property | Value & Unit |

| Density (Specific Gravity) | 1.47 |

| Ultimate Tensile Strength | 52MPa |

| Yield Strain | 5.5% |

| Compressive Strength | 66MPa |

| Tensile Modulus | 4000MPa |

| Hardness Shore D | 85 |

| Poisson’s Ratio | 0.38 |

| Design Stress | 28MPa |

| Ring Bending Modulus (3 mins) | 4000MPa |

| Ring Bending Modulus (50 years) | 1800MPa |

Thermal Properties

Thermal Properties

| Property | Value & Unit |

| Coefficient of Thermal Expansion | 7 x 10-5/°C |

| Thermal Conductivity | 0.138W/m.K |

| Specific Heat | 1047 J/kg/°C |

| Vicat Softening Temperature | >79°C |

| Allowable Operation Temperature | 50°C |

Typical Fire Resistance Properties

| Property | Value & Unit |

| Flammability | Will not support combustion |

| Ignitability-AS 1530.3* | 7 |

| Smoke development- AS 1530.3* | 9 |

| Spread of flame-AS 1530.3* | 0 |

| Heat evolved - AS 1530.3* | 2 |

Typical Electrical Properties

| Property | Value & Unit |

| Volume Resistivity | 1016 ohm.cm (60% RH) |

| Surface Resistivity | 1013 - 1014ohm |

| Power factor | 0.015 - 0.020 at 200C |

| Dielectric constant | 3.4 - 3.6 at 25 0C (60HZ) |

Temperature Effect On Pressure Rating

Apollo® pipes are suitable for service temperatures ranging from 0°C and 50°C. For temperatures above 20°C provision must be made for pressure re-rating. These re-rating factors are the same used for PVC-M and PVC-U.

Thermal Re-rating Factors*

| Maximum service temperature 1°C) | Multiplication factor for pressure re-rating |

| 20 | 1.00 |

| 25 | 0.94 |

| 30 | 0.87 |

| 35 | 0.78 |

| 40 | 0.70 |

| 45 | 0.64 |

| 50 | 0.58 |

*Based on ISO 4422-2 Pipes and fittings made of un-plasticized polyvinyl chloride (PVC-U) for water supply Part 2: Pipes (with or without integral sockets)

Chemical Resistance

Resistance of PVC-O pipe and elastomeric seals to reaction with, or attacked by, the chemical agents listed in the 'Chemical Resistance Guide' has been determined by research, investigation and reference to data from international and local Source.

Information provided is intended as a guide only Due to the complexity of some organic chemical reactions, it is suggested that in critical applications, additional long-term testing be performed.

Data provided should not necessarily be regarded as applicable to all exposure durations, concentrations and working conditions likely to be encountered.

PVC has exceptional resistance to attack from high concentrations of alkalis and acids, except for strong oxidising agents at maximum or near maximum concentrations. The material is not recommended for use with aromatic and chlorinated hydrocarbons, ketones, esters and ethers.

Product Details

Product Details

Standards and Approvals

Iplex Apollo® PVC-O pipe is manufactured to the Australian Product Standard under third-party accredited Quality Management System (QMS) conforming to AS/NZS ISO 9001.

Apollo® PVC-O pipe has ISO Type 5 third-party StandardsMark Certification, License number SMKP20188 in accordance with AS/NZS 4441 “Oriented PVC (PVC-O) pipes for pressure applications”.

Apollo® PVC-O pipe was appraised by Water Services Association of Australia (WSAA) – PA 1612.

Rubber Ring Seals

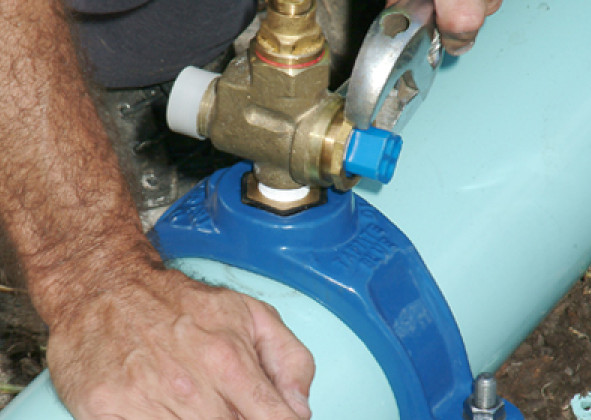

The BLUEseal joint is a spigot and socket joint comprising of the Forsheda EPDM rubber gasket moulded onto a distinctive blue polypropylene retaining ring. These gaskets are normally supplied factory fitted in the pipe sockets but are also designed for field installation where necessary.

The gasket complies with, BS EN 681 and have a UK Kitemark.

Part 1 and 3 of AS/NZS 1646 "Elastomeric seals for waterworks purpose" takes cognizance of BS EN681.

Test regimes used to certify the BLUEseal joint include those of ISO 13846 for pressure, ISO 13844 for vacuum performance and AS/NZS 4020 for drinking water applications.

Colour and Markings

Iplex Apollo® PVC-O pipes are colour coded as per AS/NZS 4441 to easily distinguish between the different types of pipes applications.

Apollo® pipe colour identification

| Product | Application |

| Apollo® PVC-O Blue | Drinking water |

| Apollo® PVC-O Purple | Recycled water |

| Apollo® PVC-O Cream | Pressure sewerage |

Environment Credentials

Iplex Apollo® PVC-O pressure pipe is certified to confirm to the Best Environmental Practice PVC (BEP PVC) provisions of AS/NZS 1260.

The Green Building Council of Australia (GCBA) has defined the standards for best practice environmental performance for PVC manufacturing, against which Iplex’s processes have been audited by an independent certifying body. These permits users of Iplex PVC-O pressures pipes to claim positive PVC Credit Points under the GBCA’s Green Star Rating Scheme. Learn More

Iplex Pipelines has published verified Environmental Product Declaration (EPD) on our range of PVC-O Pressure Pipes. EPD’s are third party certified documents based on ISO 14025 and EN 15804 Standards that communicate transparent and comparable information about the life-cycle environmental impact of a product or service. Specifically, product declarations include information on the environmental impact of raw material acquisition, energy use and efficiency, composition of materials and chemical substances, emissions to air, soil and water and waste generation.

Apollo® PVC-O Pressure Pipe Range and Dimensions

Iplex Apollo® PVC-O pressure pipes are available in Series 2 in PN12.5 or PN16 respectively. Pipes are manufactured in accordance with AS/NZS 4441 and design coefficient C=1.6.

Apollo® PVC-O Fittings Range

Conventional socketed fittings complying with AS/NZS 2280 - 'Ductile Iron Pressure Pipes and Fitting and VISAA TN2' are recommended for use with ApolloBLUE® Series 2 pressure pipes.

All Iplex PVC-O water systems have a complete range of bends, tees, reducers and flange-spigot pieces are available from Iplex with rubber ring socket in size DN100 to DN300.

Ductile iron fittings can be protected from corrosion with the following:

- Polymeric coated (preferred)

- Cement lining and polyethylene wrap

- Epoxy coating

All standard ductile iron fittings supplied by Iplex have both an internal and external polymer coating.

Ductile iron fittings used with Apollo® OPVC pipes should be manufactured with socket lengths equal to or greater than the dimensions in the table below. These dimensions are necessary to allow for Poisson’s contraction when fully pressurised to class head. Where a flange connection is required a flange socket adaptor may be used.

Ductile iron sockets joint configuration (AS/NZS 2280)

| Normal diameter DN | Minimum insertion depth(mm) | Typical chamfer length (mm) | Allowable joint deflection (degrees) |

| 100 | 42 | 10 | 3.5 |

| 150 | 50 | 10 | 3.5 |

| 200 | 58 | 10 | 3.5 |

| 225 | 52 | 10 | 3.5 |

| 250 | 62 | 10 | 3.5 |

| 300 | 71 | 10 | 2.5 |

Reference: WSAA TN2 issue 2 "Guidelines for the use of ductile iron elastomeric joint fitting with plastic pipes"

Design

Apollo® PVC-O Hydraulic Design

Apollo® PVC-O Structural Design

Handling & Storage

Handling & Storage

Apollo® PVC-O Handling and Storage

Installation & Testing

Installation & Testing

Apollo® PVC-O Installation

Apollo® PVC-O Testing

FAQ

Frequently Asked Questions

Other PVC Pressure System products you may like…

Need help?

To speak with an Iplex sales & service team member